Once you have identified the type of motor you need, it is necessary to choose the right type of gearhead and the correct reduction ratio for your electric motor. In this article, we will explain how to calculate this value.

The reduction ratio is one of the most important factors when choosing a gear motor solution to apply to an automation project. The reduction ratio determines the resulting RPM and output torque.

In this article:

- What is the reduction ratio

- Gearbox types

- How to calculate the reduction ratio

- How can Micro Motors help you in choosing the right gear ratio?

What is the electric gear motor ratio (reduction ratio)

Any electric motor has speed and torque determined by the technical characteristics set by the manufacturer. Often to meet the desired output speed and torque of the specific project it is necessary to couple a gearbox to the motor.

The task of a speed reducer is precisely to reduce the input speed of the motor to adapt it to the one required by the application. Reduction ratio (or electric gear motor ratio), therefore, means the ratio between input and output speed and it is the result of the type and number of gears inside the gearbox.

Do you need more information about reduction ratio?

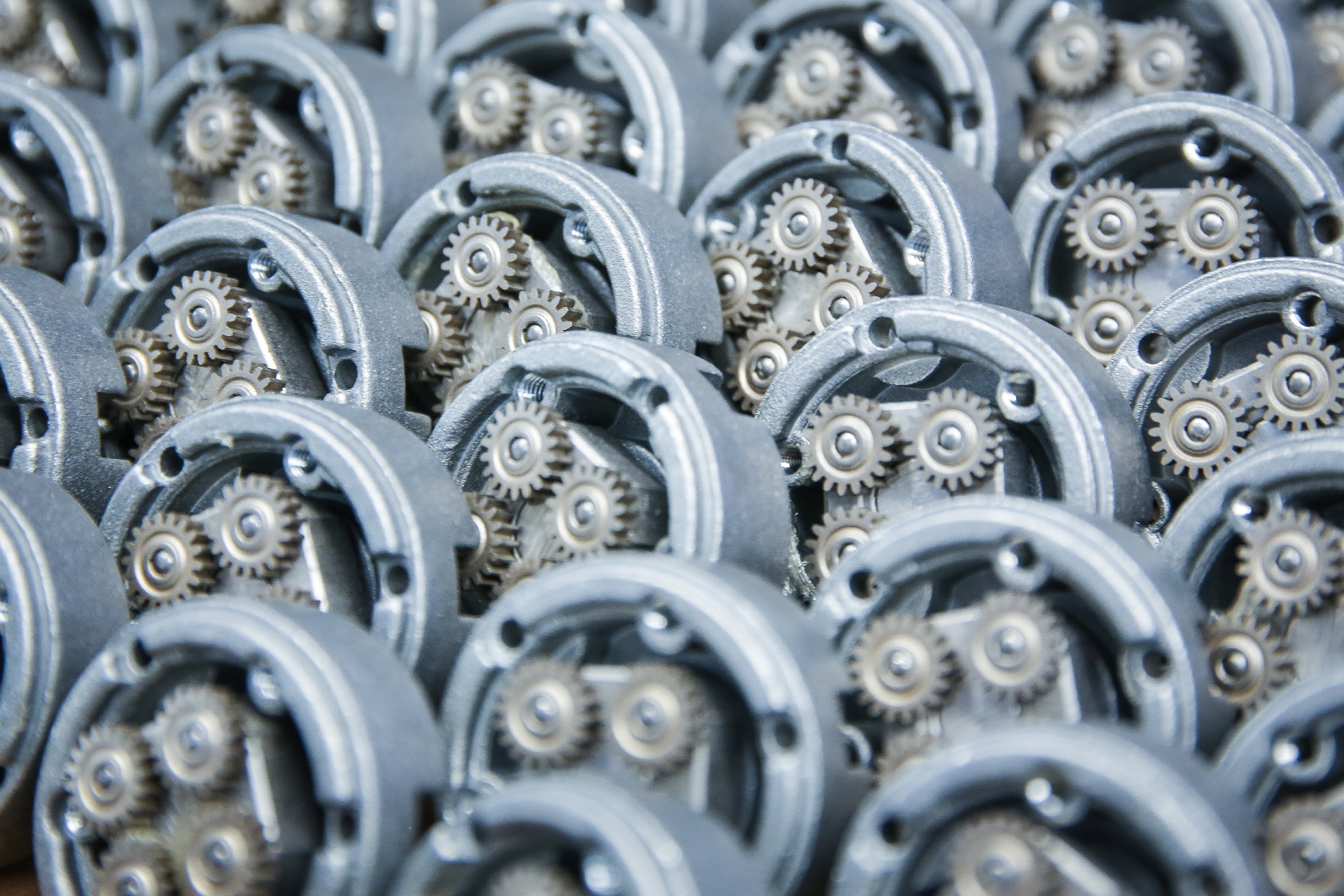

Gearbox types

There are two main types of gearboxes, spur gearbox and planetary gearbox. Each of them has its own advantages and characteristics and a different way to calculate the motor gear ratio.

Spur gearbox: this is the most common and cost-effective type of gearbox, where the gears are coupled in a drive train with a 1:1 ratio. For this type of gearbox Micro Motors uses gears made of brass, sintered steel or thermoplastic materials to lower the noise level.

Planetary gearbox: the planetary gearbox is the result of the coupling between a pinion and a satellite that works on an outer ring gear. This type of coupling generates more torque in the same space compared to a conventional spur gearbox. The gears used by Micro Motors are made of either steel, sintered steel or thermoplastic materials to reduce the noise level.

How to calculate the electric gear motor ratio (reduction ratio)

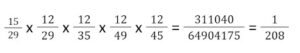

Spur gearbox gear reduction ratio

In the case of spur gearbox, the reduction ratio is the relationship between the number of teeth of the two gears coupled together.

Example:

For a spur gear motor which has 5 gears connected to each other, the calculation of the reduction ratio can be made as follows:

Which means that the reduction ratio of a gear motor with these features is 208:1.

Which means that the reduction ratio of a gear motor with these features is 208:1.

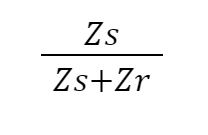

Planetary gearbox gear reduction ratio

The reduction ratio of a planetary gearbox is the correlation between the number of teeth of the pinion (sun gear) and the number of teeth of the outer ring gear on which the satellites turn.

The mathematical formula to calculate it is the following:

- Z = number of teeth

- s = sun gear

- r = ring gear

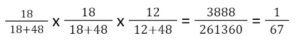

Example

Three stages planetary gear motor composed of:

- Two stages with 18 teeth sun pinions and 48 teeth outer ring gear;

- One stage with 12 teeth sun pinions and 48 teeth outer ring gear.

Calculation:

Which means that the reduction ratio of a gear motor with these features is 67:1.

Which means that the reduction ratio of a gear motor with these features is 67:1.

Once you have identified the most appropriate motor and gearhead for your application you must choose the right gear ratio based on the required number of output revolutions (RPM) of the outgoing shaft and the needed torque for your application.

How can Micro Motors help you in choosing the right gear ratio?

Micro Motors’ commitment is to help you find the optimal solution for your project.

Thanks to our technical experience and cooperating with our customers, sharing all the information regarding their requirements, we can assist you in selecting the most appropriate gearmotor.

Micro Motors also provides an alternative tool you can utilize to consult the available solutions, on our website you can find a chart with all the main parameters which you can autonomously select to identify the appropriate gearmotor.

Do you need more information to help you choose the correct gearmotor?